ColorWorkDesk: How Spectrophotometers Work

Modern colorimetry relies on spectrophotometers—precise and reliable instruments capable of measuring the composition and optical properties of materials. These measurements are crucial across various fields, including chemistry, physics, biology, and manufacturing industries.

In this article:

- The Structure of a Spectrophotometer

- Measuring an Object’s Reflection

- Measuring an Object’s Transmission

- How a Spectrophotometer Works

- Spectral Measurement by Points and Intervals

- Spectrophotometers, Spectrocolorimeters, and Colorimeters: A Classification of Measurement Instruments

- Illumination Problems and Solutions

- Transforming Data into XYZ Tristimulus Values

- Mapping the CIElab Color Space

- ColorWorkDesk Spectrophotometers: Redefining Traditional Colorimetry

The Structure of a Spectrophotometer

A spectrophotometer for colorimetric applications performs two fundamental functions: illuminating an object and quantifying the light reflected or transmitted by the material.

This is achieved through two primary components:

- A physical illuminator: Consisting of an incandescent, Xenon, or LED lamp, it irradiates the material being measured with neutral (white) light.

- A probe: Its purpose is to capture the light reflected or transmitted by the illuminated object. The optical/electronic components within the instrument process this light, converting it into spectral values for the operator.

The concepts of reflection and transmission are essential to understanding how a spectrophotometer works.

Measuring an Object's Reflection

Analyzing the reflection of a material is useful for studying opaque and semi-opaque materials, such as paints, fabrics, and metals, to determine their optical properties.

In reflection measurement, the probe in the spectrophotometer collects the light reflected from the object’s illuminated surface. Here, the illuminator and probe are positioned on the same side relative to the object.

Reflection measurement occurs when the light produced by the spectrophotometer does not fully pass through the material but interacts with it, causing diffusion and absorption, which result in reflection.

Reflection is the portion of emitted light that actually returns to the probe and can range from 0% (in cases of maximum absorption and diffusion) to 100% (in cases of total reflection). Intermediate percentages indicate that only a portion of the light is reflected, while the rest is selectively absorbed by the object or diffused in other directions.

The percentage of reflection measured by the probe is translated by the spectrophotometer into spectral values.

Measuring an Object's Transmission

Transmission measurement is more suitable for analyzing the optical properties of transparent or semi-transparent objects, such as glass, transparent plastic, and liquids.

In this case, light is directed at one side of the object, and the probe is placed on the opposite side to collect the transmitted light, which has passed through the transparent material.

In transmission, light interacting with the material may experience selective absorption and/or slight diffusion. While the primary goal is to define color, the amount of transmitted light also provides information about the material’s transparency.

The only significant variable in this type of measurement is the material itself.

How a Spectrophotometer Works

A spectrophotometer for colorimetric applications operates by measuring light in the visible range perceived by the human eye, from 400 to 700 nanometers—an interval covering all visible light wavelengths.

Using monochromators, key components of spectrophotometers, the instrument decomposes the light from the material into monochromatic sources, covering the entire 400-700 nanometer range.

These sources are then recorded by a series of photodiodes that measure the light intensity at each wavelength.

This allows for the creation of a precise spectral measurement curve, providing detailed data on the material’s optical properties.

However, since it is not feasible to include infinite probes to measure every possible wavelength, small measurement intervals are used, and mathematical interpolations estimate missing data.

Measuring in small intervals within this range is essential for accurately representing the material’s spectral properties.

Spectral Measurement by Points and Intervals

To obtain a unique spectral measurement, the minimum required interval is 20 nanometers, corresponding to 16 measurement points.

Although modern spectrophotometer technology can break light into 256 points, current data processing software typically uses 31 measurement points, with a 10-nanometer interval.

For colorimetric analyses, this level of detail (31 points) is sufficient for accurate and reliable results in most practical applications, balancing precision and processing time.

Using more measurement points would not significantly improve accuracy but would increase processing time and operational costs.

Spectrophotometers, Spectrocolorimeters, and Colorimeters: A Classification of Measurement Instruments

Instruments for spectral measurement are classified based on the number of measurement points:

A spectrophotometer must have at least 16 measurement points.Instruments with fewer points are called spectrocolorimeters (typically 8 points) or colorimeters (3 points—one for each primary color: blue, red, and green).

This classification reflects each instrument’s precision and ability to provide detailed spectral data.

Illumination Problems and Solutions

One potential issue with measurement instruments is the type of illuminator used.

While it has been stated that the only variable in color measurement is the material, spectral measurements can vary based on the type of illuminator in the spectrophotometer—LED, fluorescent, or incandescent lamps. For instance, white light versus yellow light illuminating the material can result in different reflections and, therefore, different perceived colors of the same object.

This problem can be addressed by working relatively—measuring the illuminator’s energy and relating it to the energy reflected by the sample.

This technique ensures accurate and consistent measurements, regardless of the illuminator type.

Transforming Data into XYZ Tristimulus Values

While providing unique measurements, the previously described methods primarily measure an object’s reflection.

To define color perception, it is necessary to consider the light source’s properties and the human eye’s or probe’s reception capabilities.

This is why tristimulus values are used today, allowing the quantification and prediction of color in terms of red, green, and blue energy.

As mentioned, the spectrophotometer’s ultimate goal is data collection. These data are automatically converted into XYZ tristimulus values, representing the amounts of red (X), green (Y), and blue (Z) light perceived by the human eye.

Mapping the CIElab Color Space

While XYZ tristimulus values are useful for estimating color, they do not fully align with human perception, which includes lightness and gradations of red/green and yellow/blue (Hering’s opponent-process theory).

Therefore, XYZ values are converted into the CIElab color space, where:

- The vertical L-axis represents lightness,

- The “a” Cartesian axis defines the red-green tendency,

- The “b” Cartesian axis defines the blue-yellow tendency.

- This detailed color mapping provides a precise representation of the sample’s colorimetric characteristics, allowing for objective and quantitative color evaluation and comparison.

CIElab mapping is a fundamental tool for quality control and color standardization across various industries.

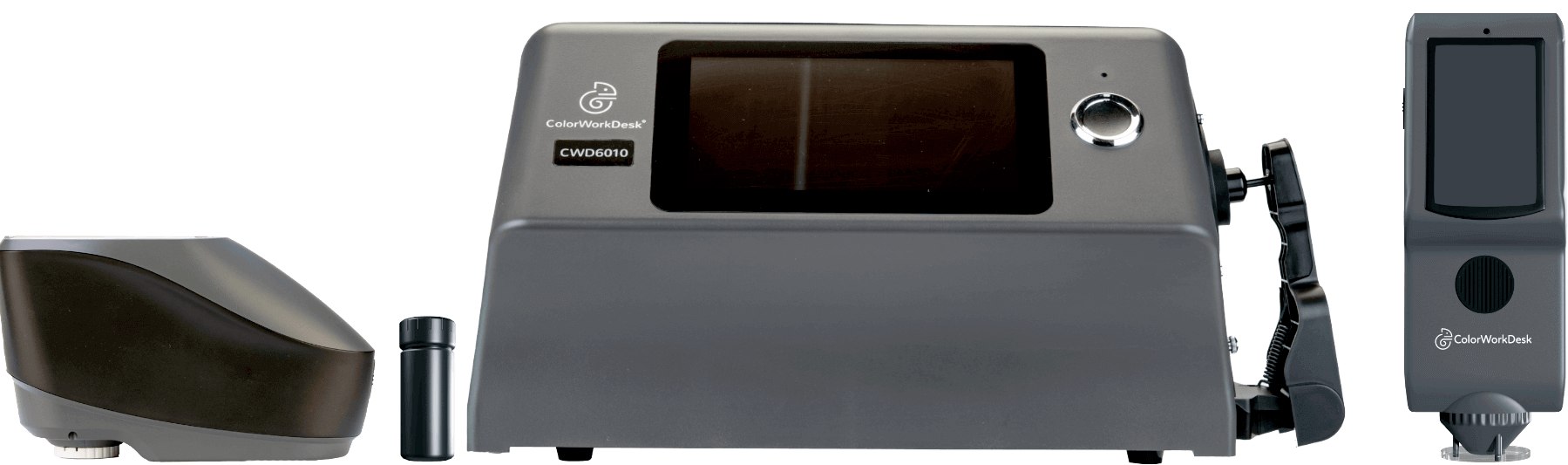

ColorWorkDesk Spectrophotometers: Redefining Traditional Colorimetry

The ColorWorkDesk (CWD) line of benchtop and portable spectrophotometers marks a revolutionary advancement in color measurement. These advanced tools enable the evaluation of any material’s color in any context, thanks to their ability to operate through both reflection and transmission.

This versatility ensures comprehensive and accurate color measurement for a wide range of applications.

Choosing CWD spectrophotometers means equipping yourself with highly performant devices capable of seamlessly integrating with modern digital technologies, such as apps, cloud, and servers.

This distinctive advantage sets them apart in the colorimetry industry, moving beyond outdated traditional methods and offering faster, more precise, and more complete color measurements.